One of the biggest fundamental challenges of microchip manufacturing is the balance between the performance they offer and the control of their operating temperature, and what could solve this problem are synthetic diamonds and ultra-pure glass. These components could completely change the future of processors and bring us much lower temperatures and at the same time up to three times higher performance.

Those who follow the technology sphere closely know that this decade has seen diminishing returns, especially when it comes to CPU temperature control. Progress in both GPU and CPU architectures has been slow in this regard, but designers and chip manufacturers have been thinking about this issue for a long time and coming up with new solutions to this problem.

Managers and employees of the companies “Diamond Foundry” and “Intel”, which deal with these problems in different ways, talked about this with the journalists of the “WSJ” portal.

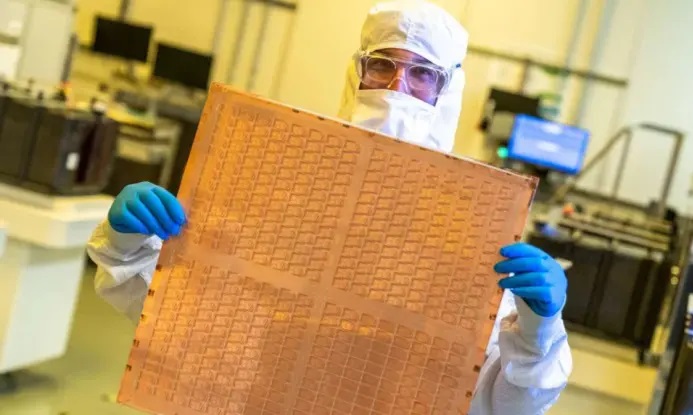

This diamond factory produces synthetic diamond wafers, apparently the largest of their kind, at least in diameter, precisely for use with silicon microchips. Such wafers allow these chips to work at least twice as fast as their base speed, claims the representative of this company, Martin Roshaisen.

Lab tests of the as-yet-unreleased Nvidia GPU processor reportedly yielded three times better performance than a normal chip built on standard manufacturing materials. That sounds pretty impressive, but it’s a little hard to believe the company’s claims without publicly available tests.

On the other hand, the well-known technology name “Intel” instead focuses on the production of refined glass for the substrates on which the processor is “mounted”. This method is already being tested in Intel factories and should be presented in the second half of this decade, which means by 2031 at the latest. Instead of cooling, purified, so-called ultra-transparent glass is used to improve energy efficiency and communication between chips, although of course greater energy efficiency is also good for cooling the processor.

Both of these new methods of developing processors, as far-fetched as they may seem now, sound quite promising and could bring about a very different future for processors than we might have expected. Also, if the Diamond Factory method proves to be good, its technique may be adopted by other manufacturers, so we don’t necessarily see it as the only supplier of this type of chip.

The same portal that did the interview cites other companies that provide their own polycrystalline wafers that are easier to synthesize, such as Coherent or Element Six, which offer even larger diamonds.

As we slowly approach the new decade, a major upheaval in hardware manufacturing could be just around the corner, where the silicon now used in chip manufacturing could end up in history.

However, the price and availability of such materials could also increase the price of the processor, so silicon will certainly remain available for some time even after the eventual launch of a new manufacturing method.